Commercial EPDM Roofs in the Greater Twin Cities Area

Ethyleen Propylene Diene Monomer Roofing Contractor – Serving the Greater Twin Cities Area

Ethyleen Propylene Diene Monomer Roofs (EDPM)

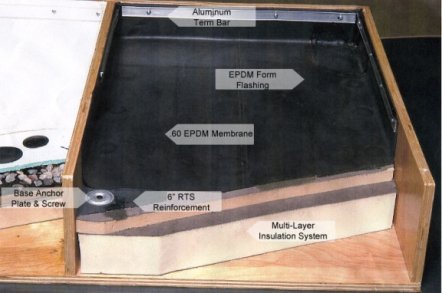

EPDM, or rubber roofing systems, consist of three types of installations. Totally adhered membranes are glued to a mechanically attached insulation board. Mechanically attached membranes are screwed to the substrate insulation directly, while a ballasted system is loose laid and covered with rock.

Rubber roofing continues to evolve with faster, better and more user-friendly components. The single biggest drawback for rubber roofs is the extremely low puncture resistance. Since warranties do not cover holes, extreme care must be taken so as to not damage the roof surface. Some buildings are simply not good candidates for rubber, requiring either a PVC membrane or a built-up membrane for high traffic areas.

EPDM Benefits

- Flexibility in design and installation

- Lightweight in some cases

- Ease of installation

- Easy to locate punctures (adhered and mechanically attached)

EPDM Drawbacks

- Low puncture resistance

- Inherent shrinking of membrane

- Black membrane heats up considerably

- Many inexperienced contractors install it, as no equipment is required

- Odor associated with solvent-based glues and primers

- Extreme difficulty locating punctures in ballast or re-roof

EPDM Rubber Roofing Options

Graveled (Ballast System)—Black

This system consists of rubber membrane roofing (45 or 60 mil thickness) that is essentially loose laid over substrate insulation. It is mechanically attached at the perimeter by way of a RTS (reinforced termination strip) anchored with screws and plates into the building structure. The loose laid membrane is then covered with river rock at a rate of approximately 10 pounds per square foot. The gravel keeps the membrane in place, as well as offering a small amount of protection from traffic. This system is the heaviest of all those available, and leaks within the field are very difficult to locate. This system is best for large expanses of roofing where access to the roof will be limited.

Mechanically Attached—Black

This system consists of rubber membrane roofing (45 mil or 60 mil thickness) in roll widths of 7’ or 10’. Mechanical fasteners are installed into the structure at the roll edges, which are covered by the next succeeding roll.

Fully Adhered—Black

This system consists of rubber membrane roofing 45 mil, 60 mil or 90 mil that is glued directly to the substrate insulation. Mechanical fasteners are kept to a minimum, and no gravel ballast is necessary. This system is the best rubber system on the market. It works well for all applications, but becomes somewhat cost prohibitive on certain projects. Bear in mind that rubber roofing is prone to puncture and care must be taken even on a fully adhered system.

If you would like more information please give us a call or contact us with any of your commercial or residential roofing services questions.

We Have You Covered

- Fully Insured

- Bill Insurance For You

- 24/7 Emergency Services

- Over 80 Years of Experience

- MN Builder Contractor Lic # 4229

- Residential & Commercial Services